Trenchless Repair

No-Dig Sewer & Water Line Repair with Advanced Pipe Lining Technology

Need pipe repair without destroying your yard? Water Pro specializes in trenchless sewer repair and water line replacement using cutting-edge pipe lining technology. Our modern, no-dig approach eliminates excavation, preserves landscaping, and completes repairs 70% faster than traditional methods.

With over two decades of trenchless expertise serving the Greater Toronto Area, we've helped 5,234+ families restore their plumbing systems without the disruption, expense, and mess of traditional digging. Our advanced trenchless technology repairs sewer lines, water lines, and drain systems from the inside—no trenches required.

What is Trenchless Pipe Repair?

Trenchless pipe repair is a revolutionary, no-dig technology that fixes sewer lines, water lines, and drain systems from the inside—without destroying your property. Using advanced pipe bursting or pipe lining methods, we access damaged pipes through small entry points and restore them completely without traditional excavation. This innovative approach provides complete plumbing solutions.

Water Pro specializes in trenchless sewer repair, trenchless water line replacement, and pipe lining services throughout the Greater Toronto Area. Our modern approach eliminates the need for yard excavation, preserves landscaping and hardscaping, reduces project timelines by 70%, and costs 30-50% less than traditional methods. Looking for expert camera inspection or hydro jetting? Call (647) 554-4356 for expert trenchless repair—same-day service available 24/7.

Advanced Trenchless Technology Solutions

Modern pipe repair without excavation—trenchless sewer repair, water line replacement, and pipe lining services that preserve your property while delivering superior, long-lasting results.

Trenchless Repair Services

Trenchless Sewer Repair

No-dig sewer line repair using pipe lining technology. Minimal disruption, 50+ year lifespan.

Trenchless Water Line Replacement

Replace damaged water lines without excavation. Preserve landscaping and driveways.

Epoxy Pipe Lining

Cure-in-place pipe lining creates seamless, corrosion-resistant pipe. 50+ year warranty.

Pipe Bursting Technology

Replace severely damaged pipes by bursting old pipe and pulling new one through.

Spot Repair (Trenchless)

Targeted repairs for localized damage using sectional lining. Fast, cost-effective solution.

Video Camera Inspection

HD camera inspection identifies pipe damage. Essential for trenchless repair planning.

Emergency Drain Service

Available 24/7, 45-minute response, first-visit solutions. Call (647) 554-4356

Preventative Maintenance

Annual maintenance program includes camera inspections, light hydro jetting, and debris removal. Just $89 per inspection prevents costly emergency repairs and water damage.

Service Comparison Guide

| Service | Starting Price | Response Time | Warranty | Best For |

|---|---|---|---|---|

| Clogged Drain Repair | From $149 | 45 min | 90 days | Sinks, tubs, showers blockages |

| Slow Drain Repair | From $99 | 45 min | 90 days | Preventing complete blockages |

| Drain Backup Solutions | From $199 | 30 min | 90 days | Water backing into home |

| Sewer Backup Repair | From $299 | 30 min | 2 years | Serious sewer problems |

| Trenchless Sewer Repair | From $399 | Same day | 2 years | Sewer line damage (no digging) |

| Drain Camera Inspection | From $179 | 45 min | 30 days | Diagnosing hidden problems |

| Hydro Jetting | From $249 | 45 min | 90 days | Grease and buildup removal |

| Emergency Drain Service | From $349 | 15 min | 2 years | Urgent situations 24/7 |

| Preventative Maintenance | From $89 | 45 min | 1 year | Routine drain care |

All prices are starting prices. Contact us for exact quotes based on your specific situation.

Trenchless vs Traditional Pipe Repair: Complete Comparison

Understanding the dramatic differences between modern trenchless technology and outdated excavation methods helps you make the right choice for your property and budget.

Why Trenchless Outperforms Traditional Excavation

Trenchless Method

- ✓ Minimal Excavation: Only 2-3 small access points (2-4 feet each) at pipe ends required

- ✓ Landscaping Preserved: No destruction of lawns, gardens, driveways, or hardscaping

- ✓ Faster Completion: 1-3 days from inspection to final cure vs 1-2 weeks for excavation

- ✓ Lower Total Cost: 30-50% savings when factoring restoration, permits, traffic control

- ✓ Superior Durability: Seamless, jointless epoxy liner lasts 50+ years with manufacturer warranty

- ✓ Minimal Disruption: Continue normal activities during repair with little impact on daily life

Traditional Excavation

- ✗ Massive Excavation: Entire pipe run dug up, often 100+ feet of trenches 4-6 feet deep

- ✗ Property Destruction: Lawns, gardens, driveways, patios, sidewalks demolished during dig

- ✗ Extended Timeline: 1-2 weeks for excavation plus additional restoration time afterward

- ✗ Higher Total Cost: Yard restoration, landscaping repair, permit fees, traffic control add thousands

- ✗ Joint Vulnerabilities: Pipe joints create weak points where roots and leaks recur over time

- ✗ Major Disruption: Heavy equipment, noise, mud, and blocked access for weeks

Real Cost Example: Traditional excavation may quote $8,000 for pipe replacement, but yard restoration adds $4,000-$6,000, landscaping repair costs $2,000-$3,000, and permit fees run $500-$1,000. Total: $14,500-$18,500. Our trenchless solution completes the same repair for $6,000-$9,000 all-in with superior results and zero property damage. Need drain cleaning services or comprehensive sewer repair solutions? We deliver trenchless technology that saves you thousands while preserving your property.

How Epoxy Pipe Lining Works: Complete Technical Breakdown

Cure-in-place pipe lining (CIPP) represents the gold standard in trenchless technology. Understanding the step-by-step process reveals why this method delivers superior results with minimal disruption.

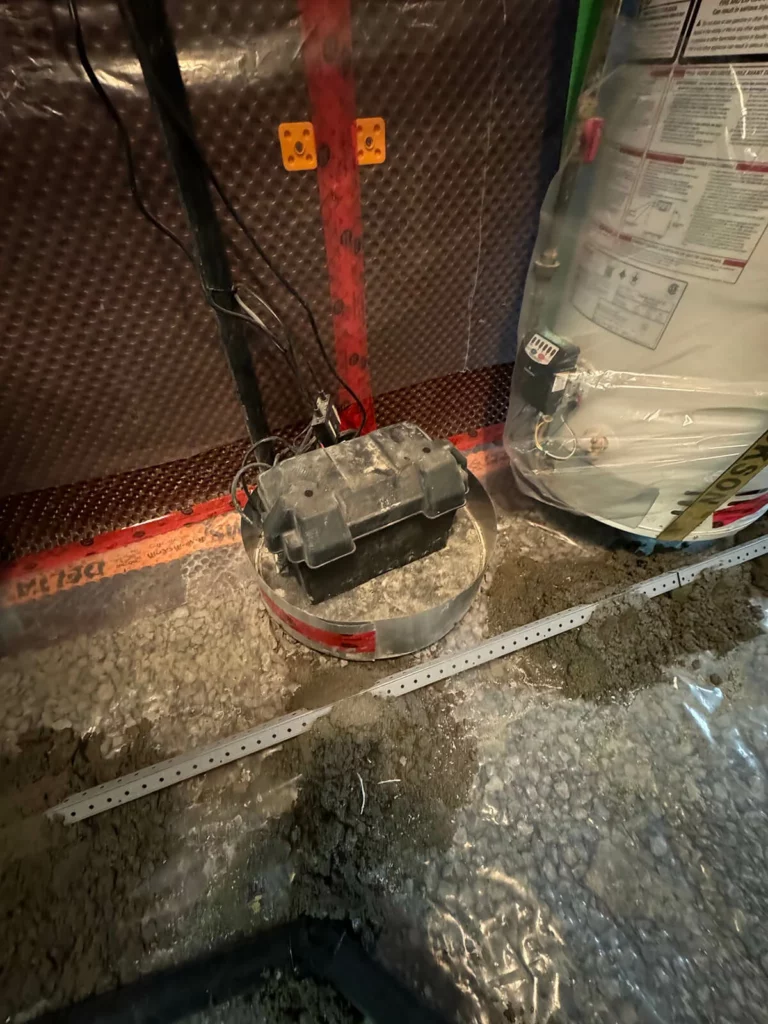

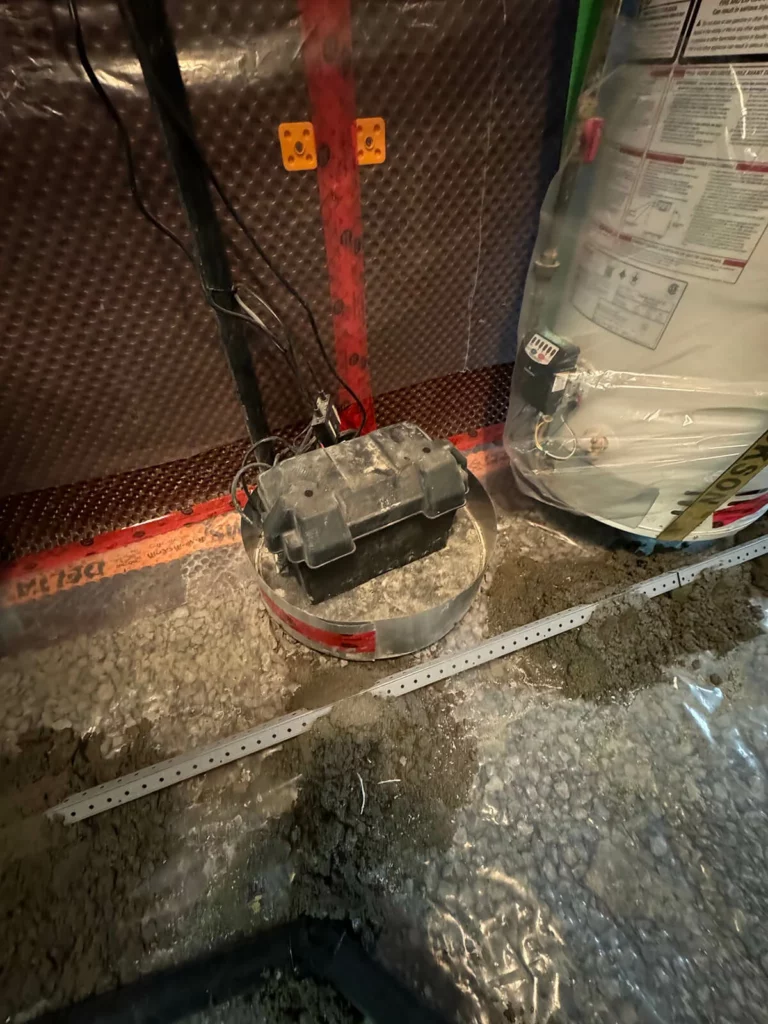

Step 1: Video Camera Inspection

Before any lining work begins, we insert high-definition video cameras through existing access points to document every inch of pipe damage. The camera reveals cracks, corrosion, root intrusion, mineral buildup, joint separation, and structural defects. This inspection creates a detailed map of damage locations, pipe diameter, and material composition. Video evidence ensures we select the correct liner thickness, epoxy formulation, and curing method for your specific situation. Camera inspection also identifies any severe collapses or misalignments that might require hybrid repair approaches combining trenchless and minimal excavation techniques.

Professional video inspection takes 30-60 minutes and costs $299-$499, but this investment prevents guesswork and ensures first-time repair success. The video recording becomes permanent documentation you can reference for insurance claims, home sales, or future maintenance planning. Need emergency assessment? Our 24/7 emergency plumbing services include rapid camera inspection within 45 minutes of your call.

Step 2: Hydro Jetting and Pipe Cleaning

Successful pipe lining requires perfectly clean pipe walls for epoxy adhesion. Our high-pressure hydro jetting equipment blasts away grease, mineral deposits, rust, debris, and root fragments using water streams at 3,000-4,000 PSI. The jetting nozzle rotates while moving through the pipe, ensuring 360-degree cleaning that removes even stubborn buildup traditional snaking misses. This thorough cleaning exposes the pipe's structural surface, allowing the epoxy liner to bond directly to the substrate.

Hydro jetting typically takes 1-2 hours depending on pipe length and contamination levels. We follow up with another camera pass to verify complete cleaning and document pre-lining conditions. This dual verification ensures optimal liner adhesion and prevents delamination failures that occur when installers skip proper preparation. Our hydro jetting service uses filtered, temperature-controlled water that won't damage pipes while delivering commercial-grade cleaning power. For comprehensive pipe maintenance, explore our water line repair services that include preventative hydro jetting programs.

Step 3: Liner Preparation and Epoxy Saturation

The liner itself consists of industrial-grade felt or fiberglass tube precisely cut to match your pipe diameter and repair length. We saturate this tube with specially formulated two-part epoxy resin engineered for structural strength, chemical resistance, and 50+ year lifespan. The epoxy formulation varies based on pipe application (sewer vs water), diameter, and local code requirements. Sewer line epoxies resist corrosive gases and bacterial growth, while water line epoxies meet NSF-61 drinking water safety standards without imparting taste or odor.

Liner saturation occurs in controlled environments using calibrated resin mixers that ensure consistent epoxy-to-fabric ratios throughout the liner length. Improper saturation creates weak spots or excessive thickness variations that compromise structural integrity. We measure resin content, viscosity, and pot life before insertion to guarantee optimal installation conditions. The saturated liner remains workable for 2-4 hours, providing adequate time for careful positioning without rushing that causes installation defects.

Step 4: Liner Insertion and Inflation

We insert the epoxy-saturated liner into your pipe through a small access point using specialized inversion equipment or pull-through methods. Inversion uses air pressure to turn the liner inside-out as it travels through the pipe, ensuring even distribution and eliminating wrinkles or folds. Pull-through methods drag the liner into position using cables attached at both ends. Method selection depends on pipe diameter, length, configuration, and access point locations.

Once positioned, we inflate the liner using air or water bladders that press the epoxy-saturated fabric firmly against the pipe walls. Inflation pressure (typically 5-15 PSI for air, higher for water) must be carefully controlled to ensure complete contact without over-stressing damaged pipe sections. The bladder remains pressurized during the entire curing cycle to maintain uniform thickness and prevent the liner from sagging or creating low spots where water might pool. Proper inflation creates seamless coverage from end to end with consistent wall thickness throughout.

Step 5: Curing Process - Heat, Steam, or Ambient

Epoxy curing transforms the saturated liner from liquid resin into rock-hard structural pipe. Three curing methods exist: hot water circulation (most common), steam injection, or ambient temperature curing. Hot water curing circulates 180-200°F water through the bladder for 2-6 hours, depending on pipe diameter and liner thickness. Steam curing uses pressurized steam for faster cure times (1-3 hours) but requires more complex equipment. Ambient curing allows 24-48 hours for room-temperature chemical reactions without applied heat.

We monitor curing temperatures, pressures, and times continuously to ensure complete polymerization throughout the liner thickness. Under-cured liners remain soft or tacky, while over-curing can cause brittleness or delamination. Temperature sensors at multiple locations verify even heat distribution, preventing hot spots or cold zones that create weak points. The curing process also activates chemical cross-linking that bonds the epoxy liner to the existing pipe substrate, creating a composite structure stronger than either material alone.

After curing completes, we deflate and remove the bladder, revealing the new seamless pipe within your old pipe. Final camera inspection documents complete coverage, proper thickness, and successful curing throughout the repair length. The cured liner achieves full structural strength after 24 hours, though limited use may be possible sooner depending on the epoxy formulation and cure method used. This proven process works for sewer lines, storm drains, water lines, and industrial process pipes from 2 inches to 96 inches in diameter. Need expert assessment of your specific pipe repair needs? Call (647) 554-4356 for detailed consultation and free quote.

Technical Specifications: Our epoxy pipe liners meet ASTM F1216 and ASTM F2019 standards for structural performance, achieving flexural strength of 4,000+ PSI and flexural modulus of 400,000+ PSI when cured. The seamless, jointless construction eliminates weak points where traditional pipe joints fail. Chemical resistance surpasses cast iron, clay, and PVC pipes, preventing corrosion from acids, bases, and organic solvents found in sewer systems.

The cured liner thickness typically ranges from 3mm to 12mm depending on pipe diameter and structural requirements, with engineered specifications ensuring compliance with ASTM D5813 for rehabilitation calculations. This isn't just a coating—it's a structural pipe replacement that restores original flow capacity while dramatically increasing service life beyond new pipe installations.

Pipe Bursting Technology: When Lining Won't Work

Severely collapsed pipes, dramatically misaligned sections, or undersized lines require complete pipe replacement. Pipe bursting accomplishes full replacement with minimal excavation—just two small access pits instead of continuous trenches.

How Pipe Bursting Works

Pipe bursting uses hydraulic or pneumatic force to fracture the existing damaged pipe while simultaneously pulling new pipe into place. A specialized bursting head slightly larger than the existing pipe diameter travels through the old pipe, breaking it into fragments that get pushed into surrounding soil. The new pipe (typically HDPE or ductile iron) follows directly behind the bursting head on a pull cable, immediately occupying the space created by the fractured old pipe.

The process requires only two excavation pits: one for the hydraulic winch that pulls the bursting head, and one for inserting the new pipe and bursting assembly. These pits measure just 4x6 feet, dramatically smaller than the 100+ foot trenches traditional excavation requires. The bursting head diameter can exceed the original pipe size, enabling simultaneous upsizing when increased flow capacity is needed. For example, we can replace a collapsed 4-inch sewer line with a new 6-inch pipe in a single operation.

Pipe bursting works for clay, concrete, cast iron, orangeburg, and certain plastic pipes. The technology handles most residential and commercial pipe diameters from 2 inches to 36 inches, with larger equipment available for industrial applications. Completion times range from one to three days depending on pipe length and site conditions. When combined with camera inspection and strategic access pit placement, pipe bursting delivers complete pipe replacement for 40-60% less than excavation while preserving landscaping, driveways, and hardscaping. Looking for comprehensive solutions? Check our sewer line repair services that include both pipe bursting and lining options.

When to Choose Pipe Bursting vs Pipe Lining

Choose Pipe Lining When: The existing pipe maintains structural integrity with damage limited to cracks, corrosion, root intrusion, or joint separation. Lining works best for pipes with minor to moderate damage where the original pipe shell can support the new epoxy liner. Lining preserves the existing pipe diameter and costs less than pipe bursting. It's ideal for sewer lines, storm drains, and water lines where internal coating restoration suffices without complete replacement.

Choose Pipe Bursting When: The pipe has collapsed sections, severe misalignment, multiple failure points, or requires upsizing for increased capacity. Pipe bursting also makes sense when original pipe material is orangeburg or heavily deteriorated clay that can't support a liner. If camera inspection reveals extensive damage across 40%+ of pipe length, complete replacement via pipe bursting often costs less than extensive sectional lining while delivering superior long-term reliability. Our experts assess your specific situation and recommend the most cost-effective, least disruptive solution based on actual pipe conditions—never a one-size-fits-all approach. Call (647) 554-4356 for professional diagnosis.

Trenchless Repair Across Toronto's Seasons

Unlike traditional excavation that becomes impossible or prohibitively expensive during winter, trenchless technology operates year-round with minimal weather-related complications.

❄️ Winter Trenchless Advantages

Traditional excavation in Toronto winters (December-March) faces frozen ground that requires expensive thawing, snowbanks that block equipment access, and sub-zero temperatures that prevent proper pipe bedding and backfill compaction. Restoration waits until spring thaw, leaving temporary patches exposed to months of freeze-thaw cycles that cause settlement and failure.

Trenchless methods bypass these obstacles entirely. Small access pits require minimal ground thawing (if any), equipment fits in tight winter spaces, and interior curing occurs at controlled temperatures regardless of outdoor conditions. We complete winter trenchless repairs in the same 1-3 day timeframe as summer projects. Your landscaping stays under protective snow cover instead of being churned into frozen mud. Many customers schedule winter repairs specifically to avoid spring landscaping damage and take advantage of off-season scheduling flexibility. Need emergency winter service? Our 24/7 emergency response handles frozen pipe crises year-round.

🌸 Spring & Summer Considerations

Spring thaw (March-May) brings peak demand for pipe repairs as winter damage becomes apparent through basement flooding, slow drains, and sewer backups. Traditional excavation tears through spring gardens, new landscaping, and freshly seeded lawns. Summer repairs (June-August) conflict with outdoor activities, pool access, and garden maintenance while creating mud, dust, and traffic disruption during peak patio season.

Trenchless technology preserves spring gardens and summer enjoyment by avoiding yard destruction entirely. The minimal disruption means your family continues normal outdoor activities during repairs. No excavation mud means no waiting weeks for yard restoration before you can replant gardens or repair hardscaping. Many customers specifically choose trenchless to protect mature landscaping, preserve pool decks, or maintain curb appeal during home sale processes. Fall repairs (September-November) offer ideal scheduling before winter while preserving autumn lawn recovery. For year-round service, explore our complete range of water line services available across all seasons.

Why Choose Trenchless Technology?

Modern trenchless repair offers superior results with less disruption, lower total costs, and faster completion than traditional excavation methods.

Preserve Your Property

No digging means your landscaping, driveways, and hardscaping stay intact. Minimal disruption guaranteed.

70% Faster Completion

Most trenchless repairs complete in 1-3 days. Traditional excavation takes 1-2 weeks plus restoration.

30-50% Cost Savings

No yard restoration, landscaping repair, or permit fees. Total project costs significantly lower than excavation.

50+ Year Warranty

Trenchless pipe lining creates seamless, corrosion-resistant pipes with 50+ year lifespan. Guaranteed durability.

Trusted by Families

Stories from our satisfied community.

Real Testimonials from Satisfied Customers

"Emergency drain backup at 11 PM on a Saturday. Water Pro was here in 30 minutes and fixed it perfectly. Professional, friendly, and fair price. Will definitely use again!"

"Had my water heater replaced. The technician explained everything, gave me options, and installed it perfectly. No surprises at the end. Couldn't be happier!"

"As a busy professional, I appreciate punctuality. Water Pro arrived exactly on time. Fixed a leaky faucet, cleaned the sink, and was done in 45 minutes. Excellent service!"

Join 15,000+ satisfied customers across the region

See Our Work in the Community

Connect with homeowners, property managers, and businesses who trust Water Pro for expert plumbing solutions.

Check It Out

Learn more about who we are and what makes us different

Watch Our Team in Action

Locations We Service

Trusted drain repair experts across the Greater Toronto Area.

6 Service Regions Ready to Help You

Toronto

3 BookingDowntown, North York, East York, Etobicoke, Scarborough

Mississauga

1 BookingOakville, Milton, Burlington, All Mississauga areas

Brampton

2 BookingCaledon, Vaughan, Georgetown, Acton

Durham Region

4 BookingOshawa, Whitby, Ajax, Pickering, Clarington

York Region

2 BookingRichmond Hill, Markham, Thornhill, Newmarket, Aurora

Peel Region

5 BookingMalton, Brampton, Mississauga, All surrounding areas

Simple 4-Step Process

We make it easy from start to finish.

Fast Path to Fixed Drains

Schedule

Call or book online in seconds.

Inspect

Full diagnosis with no pressure.

Service

Professional work with care.

Enjoy

Guaranteed results and support.

Trenchless Repair FAQs

Common questions about modern trenchless pipe repair, pipe lining technology, and no-dig sewer solutions.

8 Questions About Trenchless Technology

What is trenchless pipe repair technology? ▼

Trenchless repair is a modern, no-dig method that fixes sewer and water lines from inside using pipe lining or bursting technology. Small access points eliminate yard excavation, reducing disruption by 90% compared to traditional methods. The process takes 1-3 days versus 1-2 weeks for excavation. Call (647) 554-4356 for expert trenchless assessment.

How does trenchless pipe lining work? ▼

Pipe lining inserts an epoxy-saturated liner into damaged pipes via small access points. The liner inflates, cures, and creates a new pipe within the old one. This seamless, jointless pipe lasts 50+ years and works for sewer lines, water lines, and drain systems without digging. Our camera inspection confirms proper placement before curing begins.

How much digging is required for trenchless repair? ▼

Trenchless repair requires only 2-3 small access holes (2-4 feet each) at pipe ends. Traditional excavation digs up entire pipe runs, often 100+ feet of yard destruction. Trenchless technology preserves landscaping, driveways, and hardscaping with minimal surface impact. Most customers are amazed at how little disruption occurs compared to traditional methods.

What is the cost difference between trenchless and traditional repair? ▼

Trenchless repair costs 30-50% less than excavation when factoring total project expenses. While per-foot costs may be similar, trenchless eliminates yard restoration, landscaping repair, permit fees, and traffic control costs. Most homeowners save $5,000-$15,000 compared to traditional digging. Contact (647) 554-4356 for detailed cost comparison.

How long does trenchless sewer repair take to complete? ▼

Most trenchless repairs complete in 1-3 days from inspection to final cure. Traditional excavation takes 1-2 weeks plus additional restoration time. Trenchless technology gets your plumbing operational faster with minimal disruption to daily routines. We schedule projects efficiently to minimize inconvenience while ensuring proper curing times.

Is trenchless repair suitable for all pipe problems? ▼

Trenchless repair works for most pipe damage including cracks, corrosion, root intrusion, and collapsed sections. However, severely misaligned pipes or certain soil conditions may require traditional excavation. Our camera inspection identifies the best repair method for your specific situation. We'll always recommend the most cost-effective, least disruptive solution available.

What warranty do you offer on trenchless repairs? ▼

Trenchless pipe lining comes with a 50+ year manufacturer warranty and our 90-day satisfaction guarantee. The epoxy liner is seamless, corrosion-resistant, and stronger than original pipes. If any issues arise, we'll return at no additional cost to make it right. Your investment is protected for decades to come.

Can trenchless technology repair both sewer and water lines? ▼

Yes! Trenchless technology repairs sewer lines, water lines, and drain systems. Pipe lining works for both sewer and water applications, while pipe bursting effectively replaces severely damaged pipes of any type. We assess your specific pipe material, damage extent, and property conditions to determine the optimal trenchless method. Call (647) 554-4356 for expert trenchless consultation.